| During the 1955-1970 period, family-owned lumber businesses in the region expanded and many changes occurred in the industry. | |||||||||||

|

|||||||||||

|

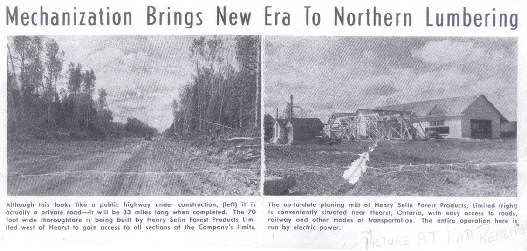

Selin Forest Products (November 1952) |

|||||||||||

| The company that underwent the fastest growth was Henry Selin Forest Products at Nassau Lake, which operated primarily in townships owned by Transcontinental Timber. | |||||||||||

| In

the late 1950s, benefiting from logging rights on vast territories, the

company reached an annual production level of close to 50 million feet

of wood, which according to many observers made it the most important softwood

sawmill east of the Rocky Mountains. The company hired hundreds of workers

and used over 200 horses in the bush before the advent of wheeled skidders

during the 60s.

The Selin company built logging roads in the forest which permitted the logging and transportation of wood both during summer and winter. The company also introduced mechanical diggers and larger sized trucks and tractors to its operations. Meanwhile, other lumbermen of the region managed to improve their production thanks to an increase in their timber supply. In addition to obtaining logging rights on Crown lands, they purchased logging rights from pulp and paper companies, contractors and settlers. Levesque’s Kabina and Ritchie mills were thus able to function year round by the 1960s. Furthermore, during this time period, a new generation of entrepreneurs got involved in the lumber industry, including René Fontaine, Réal and Yvon Levesque, the Lecours brothers and the Gosselin brothers. By the end of the 1950s, local owners banded together and created the “Hearst Lumbermen Association.” René Fontaine recounts the formation of this association: “The first meeting took place on a Sunday afternoon at Selin’s. We wanted a rebate from the CN (back then, more than 90% of finished lumber was transported by railroad). We managed to get it. After that, we kept on meeting once a month. We had diner at Levesque’s, Selin’s, my place, Gosselin’s, Lecours’ and we held meetings. We began to trust each other” (Excerpt from an interview with René Fontaine). Mr.

Roland Cloutier presided over this association for over 30 years. The association

allowed owners and managers of companies to discuss topics of common interest

and to improve their collective destiny. Having witnessed the benefits

of such a group, the association decided to establish contacts with other

sawmill owners in the province and a meeting took place in Hearst in 1965.

A year later, the Ontario Lumber Manufacturers Association (OLMA) was created.

By the end of the 1950s, local mill owners discussed the production of wood chips for sale to pulp and paper mills and the building of a plywood factory that would use aspen. Yvon Levesque left the lumber industry to undertake the construction of a plywood factory. He and his brother Hervé created the Levesque Plywood company in 1960 and built a factory that would enjoy quick success and great expansion.

Meanwhile, the Selin company was the first in the region, and probably in Ontario, to install in the early 60s, a barker and a chipper to make chips from scrap wood from the sawmill. Those chips were initially sold for a low price but the revenues they generated increased gradually. Nonetheless, sawmills continued to sell pulpwood. Because electricity was necessary to the operation of a chipper, owners of sawmills operating on steam were forced to build new mills that ran on electric power. In

the beginning of the 1960s, the Lecours and

Gosselin

families built new mills in Calstock.

J. D. Levesque

did the same in Hearst in 1962, followed by René Fontaine,

who also built in Hearst, in 1964.

Shortly after the installation of chippers in many sawmills, logs were cut and transported lengthwise, which allowed for a greater output of chips and less wood residue being left behind in the bush. The construction of new sawmills and factories, the mechanization of in-forest operations and the unionization of workers were all factors that influenced working conditions during this time span. In 1968, the Hearst Lumbermen Association created Claybelt Lumber, an independent wholesale enterprise that purchased wood from both local and outside sawmills, for example from Abitibi. This new enterprise played an important role in the lumbermen’s quest to obtain a market price as high as possible for their products. At the same time, the OLMA created a lumber classification agency to set uniform standards for wood quality, which let entrepreneurs greatly reduce problems with customers and ensure better revenues. These

initiatives, however, arrived too late for the Henry

Selin Forest Products company, which encountered financial problems

in the mid-1960s leading to its closure in 1970. Selin’s

logging rights on land belonging to Transcontinental Timber were made available

to other companies, which served to further their consolidation.

|

|||||||||||

![]()